09 Nov Choosing the right type of fire damper in ventilation ducts

Choosing the right type of fire damper in ventilation ducts

In the case of a building fire, the safety of all occupants is of utmost priority. To limit the rapid spread of fire within a building and to keep escape routes clear from smoke – which is the leading cause of death in a fire – engineers often divide the building into compartments that are separated from one another by walls and/ or floors capable of withstanding the effects of fire for a specified duration of time.

The fire resistance of such elements is specified by European standards as REI tt, where:

- R refers to the load-bearing capacity which means that the structure can withstand the effects of fire without collapsing,

- E refers to the integrity of the structure which means that cracks or openings which may allow flames of hot gases to pass through will not form into the structure,

- I refers to the insulation capacity which means that the element will not allow heat to be transferred across it to the unexposed side, and

- tt refers to the time duration for which the fire-resisting elements should provide such load-bearing, integrity and insulation characteristics in the event of a fire.

Therefore, fire separating elements required to have a fire resistance REI 120 should be capable of having a load-bearing capacity, integrity and insulation of at least 120 minutes.

What happens if ventilation ducts pass through fire-separating elements?

Unless the resistance of fire separating elements such as compartment walls/ floors is maintained, fire can spread from one compartment to another via the ventilation ducts.

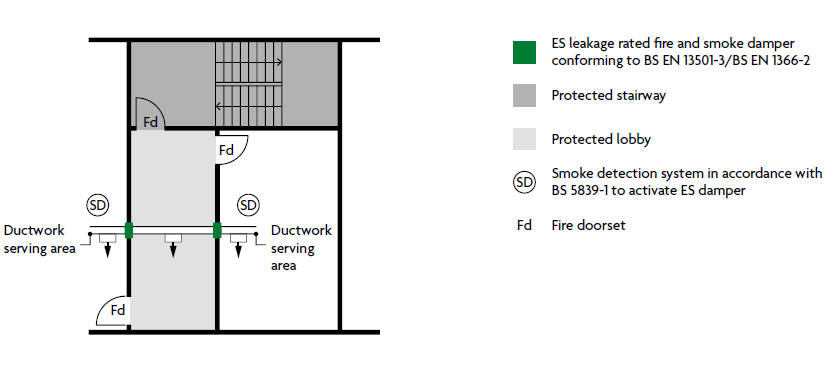

One method of maintaining the integrity of these elements is by using automatically activated fire/smoke dampers. Such systems allow ventilated air in normal conditions to pass through but prevent the passage of fire and smoke in the event of a fire.

Selecting suitable fire/smoke dampers

Fire/smoke dampers should conform to EN 15650 and should have an integrity of 60 minutes or equal to the fire rating of the fire resisting elements through which it passes, whichever is the higher.

Dampers are generally classified using the following format:

EI (VE, HO io) S tt

Where,

- E refers to the ability of the product to maintain its integrity,

- I refers to the ability of the product to maintain its separation function without developing temperatures on its unexposed surface,

- VE means that the product has been tested for vertical installations,

- HO means that the product has been tested for horizontal installations,

- io means that it has been tested inside to outside and vice versa (o-i = outside to inside, i-o means inside to outside),

- S means that the product is smoke tight, and

- tt refers to the fire-resistance time in minutes.

When installing fire/smoke dampers it is therefore important to make sure that they are classified so that they can be used in the required orientation (vertical/ horizontal).

Although Building Regulations do not specify that fire/smoke dampers need to have insulation characteristics, we at Sammut and Associates believe that it is good practice to use fire/smoke dampers with insulation rating. This is because by using fire/smoke dampers without insulation properties, there is risk that the damper will absorb the heat from the fire side and start combustion by radiation for example of the false ceiling or electrical cables located on the non-fire side.

As such, in our designs of ventilation duct systems, we always recommend insulated blade dampers over curtain-type dampers to increase the level of life and property protection of our clients. Curtain type dampers may be in compliance with EN 15650, however since the blades are made of stainless steel, they do not offer insulation rating. With insulated blade damper we can prevent risk of heat from the fire side starting a fire in the adjacent compartment by the red-hot closed steel blades.

Installing fire dampers

To ensure proper installation of fire dampers, installers should always follow the manufacturer’s installation instructions. Common to all type of dampers, fire/ smoke dampers should be sited within the thickness of the fire-separating element and be securely fixed and supported independently of the ducting so as to ensure that if the ductwork in the fire compartment collapses, the integrity between the compartments is still maintained.

For more information on why insulated blade fire dampers are desirable over curtain type fire dampers, and how to make sure that as a consulting engineer you are specifying the right type of system, or as a property developer you are investing your money in the right type of fire damper that will ensure the safety of people in the case of a fire building, speak to one of our fire safety specialists.